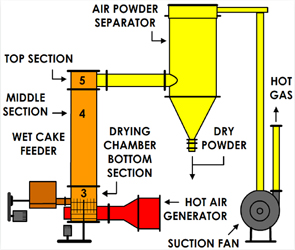

This flash dryer is useful for mechanical dispersion and for adjusting the granule size of high humidity paste type material.

Under the action of hot air and mechanical dispersion, the wet cake appears granular and gets fluidized.

Instantaneous exchange of heat and mass takes place.

The dried materials are taken in the collector as powder products.

The system consists of double shaft screw followed by mono screw to feed homogenized material into dryer housing at controlled rate.

The tangential entry of air and mechanical action of agitator help to decompose lumps enabling intimate mixing of hot air with the product, and thus ensuring drying of the product.

|

The particle classification orifice on the top of drying chamber allows finer product to pass with exhaust gas to powder collection system. The flash dryer is useful for drying sticky products, also effective against viscous materials. The simple Flash Dryer is designed lo handle materials that can be suspended directly in air, requiring removal of free moisture. Wet material is dispersed into a stream of heated air (or gas) which conveys it through a drying duct. Using the heat from the air stream, the material dries as it is conveyed. Drying takes place in a matter of seconds, and the final moisture is generally in the constant rate drying zone. |

|

|

Elevated drying temperatures can be used with many products since the flashing off of surface moisture instantly cools the drying gas without appreciably increasing the product temperature. Product is separated using cyclone, and/or bag filter. Typically, cyclones are followed by scrubbers or bag filters for final cleaning of the exhaust gases to meet current emission requirements. |

|